As a dust filter cloth manufacturer, we provide fully customizable fabrics to meet specific application needs. Options include:

We Craft Every Filter Cloth with Care

Our filter cloth are designed based on actual site conditions, not generic catalog assumptions. We help you select the right media to balance filtration efficiency, pressure drop, and service life.

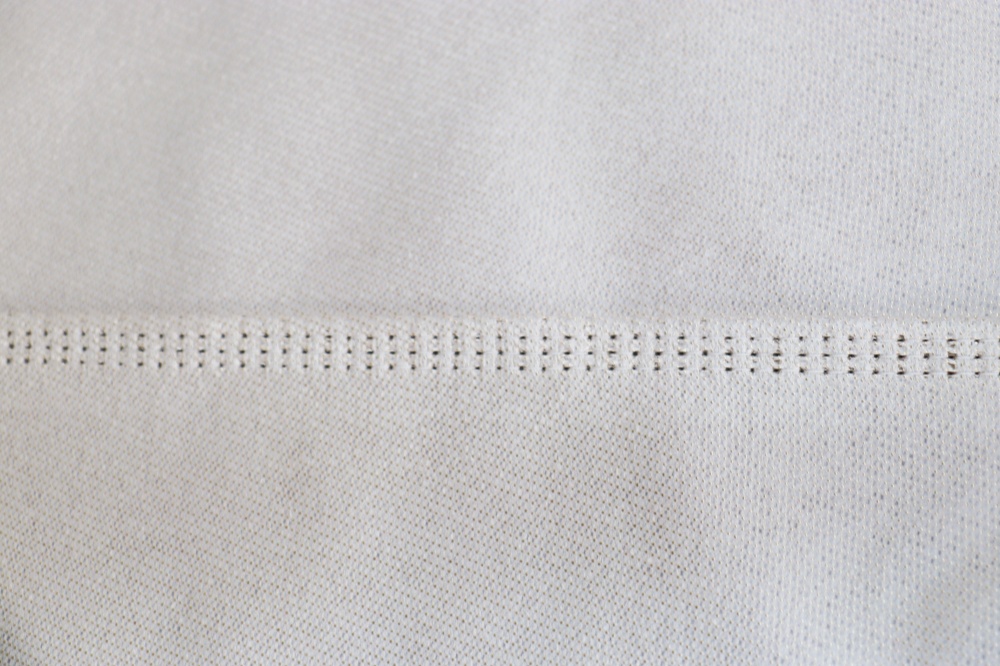

Needle-Punched Felt Filter Cloth

Needle Punched Felt Filter Media from Aokai Environtec is the essential filtration material for industrial dust collector bags. It captures fine particulates efficiently while maintaining low pressure drop and stable system performance.

Aokai’s advanced needle-punching technology creates a dense, uniform structure that forms a stable dust cake quickly — delivering high filtration efficiency (>99.9%), excellent pulse-cleaning release, and 20–50% longer bag life.

With customizable treatments (singed, calendered, PTFE membrane, antistatic, water/oil repellent, etc.), Aokai ensures low emissions, reduced energy use, equipment protection, and reliable compliance with strict regulations.

PTFE Filter Fabric

High temperature and chemical resistance up to 260°C. Ideal for waste incineration and chemical processing plants.

PPS Needle Felt

Excellent resistance to acid, alkali, and moisture. Widely used in coal-fired boilers and thermal power stations.

FiberGlass Filter Fabric

Fiberglass filter cloth, with its exceptional ultra-high temperature resistance (up to ) and lasting durability,

Nomex Fabric

The operating temperature limit for aramid is 204°C (400°F), Aramid filter bags offer good high-temperature resistance and wear resistance.

Aramid Needle Felt

It resists 240℃ high temperature and is flame-retardant, serving as an efficient filter material for dust removal in metallurgy and chemical industries.

Polymide (P84) Filter Fabric

Resistant to 280℃ high temperature with high filtration precision, it is specially designed for dust removal in waste incineration and cement kiln tail.

Polyester needle felt

Polyester filter cloth, Polyester has an operating temperature limit of 135°C (275°F) and comes in both needlefelt and woven media.

Acrylic non-woven filter cloth

Good resistance to hydrolysis and suitable for moist environments like municipal waste treatment.

Fiber Blend Series

Expertly customized with various fiber ratios, perfectly adapts to diverse operating temperatures and filtration demands。

Anti-static filter cloth

Anti-static filter cloth safely dissipates static electricity, completely eliminating the risk of dust explosions and providing a more secure and stable dust removal solution for your industrial operations.

Water and oil repellent filter cloth

Processed by special technology, water and oil repellent filter cloth has excellent water and oil repellent properties. It can effectively prevent dust adhesion and filter cloth clogging, adapt to dust removal scenarios of oily and humid flue gas, and improve both dust removal efficiency and service life.

Flame-Retardant Filter Cloth

Flame-retardant filter cloth is a specialized fabric used in dust collection filter bags for high-risk environments (e.g., welding, metal grinding, chemical plants).

Applications

Aokai provide custom felt filter cloth solutions for abrasive, corrosive, high-temperature, and explosive dust filtration.

Related Products

We also provide various high-quality filter cages, filter bags, and other accessories to offer you a one-stop dust removal solution.

Our focus is not just supplying filter bags, but reducing your total filtration cost over time.

Quality & Consistency You Can Rely On

01

Consistent raw material sourcing

02

Controlled manufacturing process

03

Strict dimensional tolerance

04

Each batch inspected before shipment

We have carried out industry university research cooperation with many top universities in China, and developed product series such as “Jiejingda“, “Cabture“, “CareClean” according to the specific working conditions of the industry.

We hold a total of 64 invention and utility patents.

High performance membraneless low resistance

Gradient structure high performance

High efficiency low resistance needle felt

Life prediction

High mechanical properties

Product digitization R&D

Low carbon and clean material research and development

Expert Online:

We have a multilingual international sales and service team fluent in English, French, German, Spanish, Portuguese, Russian, Arabic, Japanese, and Korean, ensuring smooth and efficient communication with clients worldwide.

Global Sales Engineer Team

Leadership Team

Global Technical Team

R&D Team

Technical Support:

24/7 Technical Support

(Response Time ≤ 4 Hours)

Free Filter Bag Selection Consultation Based onYour Working Conditions (Temperature Humidity/Dust Type)

Serving 16,000+ clients worldwide,Exported to more than 40 countries and regions worldwide.our filter cloth is trusted across cement, steel, power, waste incineration, chemical, and asphalt industries.

We actively participates in the global supply chain service market, and we are committed to providing customers with high-quality products and services to promote local economic development.

OEM Market

Maintenance Market

Our flexible supply chain management facilitates fast response-time to meet customer requirements and market changes.

1-Raw Material

Supplier Diversification, Material Sustitutability

2-Collaboration

Collaborative Demand Forecasting, Custom Solutions

3-Manufacturing

Quick Line Changeover & Production Switching Multi-Skilled Workforce, Modular Design & Manufacturing

4-Warehousing

Stock 500,000+ m² of common specs (PE, PPS, Aramid, PTFE) -Ship in 48 hours

From Sample Analysis to Engineered Filter Solutions

Our Services

Step 1

Sample Analysis & Application Review

- Analyze fabric structure and material composition

- Review wear patterns, clogging or failure reasons

- Evaluate dust characteristics and operating conditions

Step 2

R&D & Material Engineering

- Needle felt material selection and optimization

- Fiber blend, weight and permeability design

- Surface treatments (PTFE membrane, singeing, glazing)

Step 3

Filter Bag & Cage Design

- Accurate size and construction

- Cage wire layout and surface finishing

- Compatible with pulse jet and cleaning systems

Step 5

Fast & Transparent Quotation

-

Material specification

-

Unit price & MOQ

-

Lead time and delivery terms

Step 4

Sampling & Confirmation

- Custom samples for testing

- Performance confirmation before mass production

- Adjustments based on test feedback

Step 6

Manufacturing, QC & Delivery

- All products are manufactured under strict quality control and shipped with export-ready packaging.

Ongoing technical support is available after delivery.

Our Manufacturing Strength

With over 21 years of experience, our production facility covers more than 27000 m² and is equipped with advanced filter media and bag-making equipment to ensure consistent quality and high efficiency.

Custom Manufacturing

4,000,000㎡

Annual Filter Media Production

- Automatic Production Lines

- Oil & Water Repellency Treatment

- Heating Setting

- Singeing

- Calendering

- Lamination

3,000,000 pcs

Annual Filter Bag Production

- Automatic Multi-Task Production Lines

- Precision Sewing

- Heat Sealing

- Pinhole Sealing

- Seam Lamination

2,000,000 m

Annual Cage Production

- Filter Cages of All Shapes & Sizes

- Cage Treatments

- Silicone Coating

- Galvanizing

- Passivation (stainless steel)

Advanced Manufacturing Equipment & Technology

Partnering with a reputable and industry-leading needlefelt equipment manufacturer from Germany, Aokai operates two advanced needlefelt production lines. From fiber opening to blending, carding, web forming, crosslapping, needle punching, filter media treatment, and ePTFE lamination, we manufacture baghouse filter media in-house to ensure the highest manufacturing standards.

Lean Intelligent Manufacturing

Raw Material Selection

Mixing and Pretreatment

Intelligent Spinning & Web Formation

Precision Needle Punching Molding

Heat Setting

Singeing Treatment

Membrane Lamination

water/oil repellency

Warehouse & Stock

Quality Control

Raw material quality control

The raw materials of Aokai have undergone tests for 13 indicators in the laboratory, including fiber composition, air permeability, breaking strength and elongation at break, thermal shrinkage, moisture regain, oil content, and fiber melting point, with all test standards surpassing the relevant criteria.

Production process quality control

The factory has obtained ISO9001 and ISO14001 certifications. It operates in accordance with the 7S management standards, strictly controls product quality in line with international high-end product testing standards, retains inspection records for more than 3 years and electronic records permanently, ensuring the traceability of each batch of products.