Aokai Environtec is at the forefront of helping waste incineration plants achieve ultra-low emissions. For example, a large urban waste incineration plant in Beijing has been using Aokai’s Cabture® PT Series filter bags since 2022. These filter bags have consistently delivered stable near-zero emissions, with particulate matter emissions reliably maintained at around 3 mg/m³. This remarkable performance not only enables the plant to meet and exceed stringent environmental regulations and standards but also ensures continuous and efficient operations.

Background

The waste incineration industry, while offering a solution for waste management and energy generation, has historically faced scrutiny for its potential environmental impact. The incineration process, by its nature, releases various pollutants into the atmosphere, including particulate matter, acid gases, and heavy metals. As global awareness of air quality and climate change intensifies, there’s increasing pressure on waste incineration plants worldwide to significantly reduce their emissions. This urgent need is driving the demand for highly efficient filtration solutions.

Challenges

As of 2024, China generates over 120 million tons of hazardous waste annually, with 35% treated through incineration. This growing reliance on thermal disposal places heavy demands on air pollution control systems, especially filtration materials. Incineration flue gas contains corrosive compounds like hydrogen fluoride (HF) and hydrogen chloride (HCl), along with toxic pollutants such as dioxins and heavy metals. These harsh conditions require filter media that can endure high temperatures (≥260°C) and broad chemical exposure (pH 1–14). Conventional materials like PPS and fiberglass often fail within eight months, leading to frequent maintenance, operational disruptions, and reduced compliance with environmental standards.

Solution

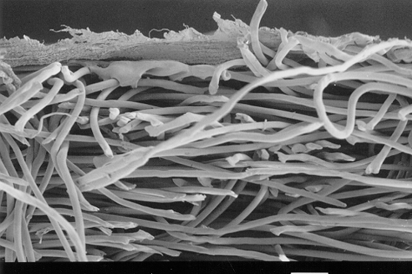

To address these critical challenges, the waste incineration plant selected and implemented Aokai’s Cabture® PT Series filter bags in 2022. Engineered for harsh operating conditions, Cabture® PT Series filter bags offer exceptional thermal stability, chemical resistance, and filtration efficiency, making it an ideal solution for achieving ultra-low emissions in waste incineration plants. The advantages of Cabture® PT Series filter bags include:

Unmatched Performance in Extreme Environments

The Cabture® PT Series filter bags excel in challenging conditions. They withstand continuous temperatures up to 240°C and peak exposures of 260°C. Demonstrating superior acid resistance, they maintain an impressive 99.98% filtration efficiency even in highly acidic environments (pH 0.5), effectively preventing fiber embrittlement from corrosive gases.

Achieving Ultra-Low Emissions

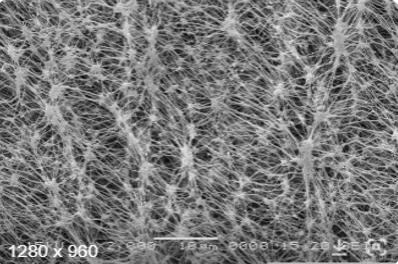

Designed for the strictest emission standards, the Cabture® PT Series filter bags deliver over 99.99% filtration efficiency for ultra-fine particulate matter in the 0.3–0.5 µm range, empowering the plant to meet and exceed regulatory requirements.

Advanced Design for Optimal Operation

Through advanced high-temperature lamination, the membrane securely bonds to the base fabric without adhesives. Its remarkably smooth surface minimizes dust adhesion, ensuring consistent and efficient cleaning throughout operation.

Inherently Flame-Retardant Safety

With an extraordinary Limiting Oxygen Index (LOI) of up to 95%, Cabture® PT Series filter bags are inherently flame-retardant. They self-extinguish when removed from open flame.

Results

The implementation of Aokai’s Cabture® PT Series filter bags has yielded remarkable results. After replacing all existing filter bags in August 2022, and following almost three years of operation, on-site inspection confirmed a dramatic performance improvement. The emissions level plummeted from 10 mg/m³ to an impressive 3 mg/m³, significantly surpassing the new regulatory standard of 5 mg/m³. This level has been consistently maintained for almost three years.

Cabture® PT series filter bags have proven to be a game-changer for the Beijing-based incineration plant, enabling it to transition to ultra-low emissions with minimal operational disruption. For more information about Aokai’s Cabture® PT Series products, please contact us.

About Aokai Environtec

Aokai Environtec is a leading manufacturer of baghouse filter media, filter bags, and baghouse accessories. Founded in 2004 and headquartered in China, our products are used in a variety of applications and industries, including asphalt plants, cement plants, mining operations, power plants, the metallurgy industry, the renewable energy industry, waste incineration plants, and other industrial facilities. We specialize in providing dust filtration solutions in the power generation and waste incineration industries. For more information, please contact Aokai.